Table of Contents

Introduction

The monotone of the familiar often blinds us to the intricacies that underpin the most mundane objects. We take the notebook, a simple canvas for thought, so ubiquitous yet significant, employed by students, professionals, and artists alike. Yet, beneath its seemingly unassuming exterior lies a testament to human ingenuity – a multi-faceted process of meticulous planning, skilled craftsmanship, and cutting-edge technology. India, a nation steeped in tradition and innovation, boasts a thriving notebook manufacturing industry.

This article delves into the unseen symphony of this art form, exploring each movement from its start to the finished product.

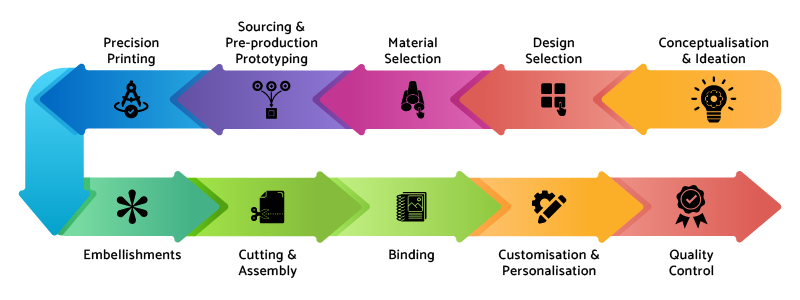

The Step-by-Step Process of Manufacturing Notebooks

1. Conceptualisation and Ideation

The journey begins with conceptualisation. This stage entails research and understanding of market trends, pinpointing target audiences such as students, professionals, and artists, and solidifying the brand’s identity. Designers also hold brainstorming sessions to generate ideas for features, size options, and functionalities.

2. Design Selection

Notebook designs cater to various preferences and are available in a plethora of styles, from sleek and minimalist to vibrantly patterned. Designers create mockups and prototypes, experimenting with colours, layouts, and branding elements.

3. Material Selection

The heart of a notebook lies in its paper quality. Manufacturers in India source paper from domestic mills or import it based on desired characteristics. Paper weight, texture, opacity, and environmental sustainability are all crucial considerations. Covers are often made from cardstock or recycled materials, complementing the paper choice and overall design aesthetic.

4. Sourcing and Pre-production Prototyping

With the design and materials finalised, manufacturers source components like glue, stitching elements, and embellishments (ribbons, pockets). Pre-production prototypes are then created to test functionality, printing quality, and binding integrity meticulously. This stage ensures a smooth and efficient mass production run.

5. Precision Printing

Modern printing presses are essential in the production of personalised notebooks. Manufacturers use offset or digital printing to ensure the high-quality replica of various design elements. This includes ruling lines for grids, lines, staves, headers, footers, and any branding or decorative elements on the cover and internal pages.

6. Embellishments

Notebooks may incorporate embellishments like foil stamping, embossing, or UV coating for added functionality. These techniques add depth, texture, and visual appeal and are often used for branding or highlighting specific features.

7. Cutting and Assembly

Large paper sheets are precisely cut to the desired notebook size using automated cutting machines. The pre-printed and possibly embellished covers are then meticulously assembled with the internal pages.

8. Binding

The binding process unites the individual components into a cohesive unit. Popular binding methods in India include:

- Stitching (saddle stitch, perfect bind).

- Glueing (square back, perfect bind).

- Spiral binding.

9. Customisation and Personalisation

In today’s market, personalisation is key. Some manufacturers offer opportunities for customised covers with printed logos, names, or even custom-designed pages. This caters to corporate clients, educational institutions, and individuals seeking a unique touch.

10. Quality Control

Maintaining high-quality standards is crucial. Rigorous quality checks ensure that personalized notebooks meet predefined specifications for paper quality, printing accuracy, binding strength, and functionality.

Final Words

From concept to creation, the journey of a personalized notebook in India is a testament to meticulous planning, skilled craftsmanship, and technological advancements. Each notebook embodies the ingenuity and dedication of individuals working behind the scenes, ready to capture your thoughts, ideas, and stories.